In many cases making a suitable allowance for the smoke control power supply size precedes the appointment of a specialist contractor. Due to this, complications may arise as the appointed contractor will be unable to offer their detailed design and equipment selections. Consequentially, the resulting incorrect estimates can be the source of costly issues in the long run. In order to avoid this, a reliable method of establishing an appropriate allowance is essential to a project.

Power supply size for Smoke Control Systems

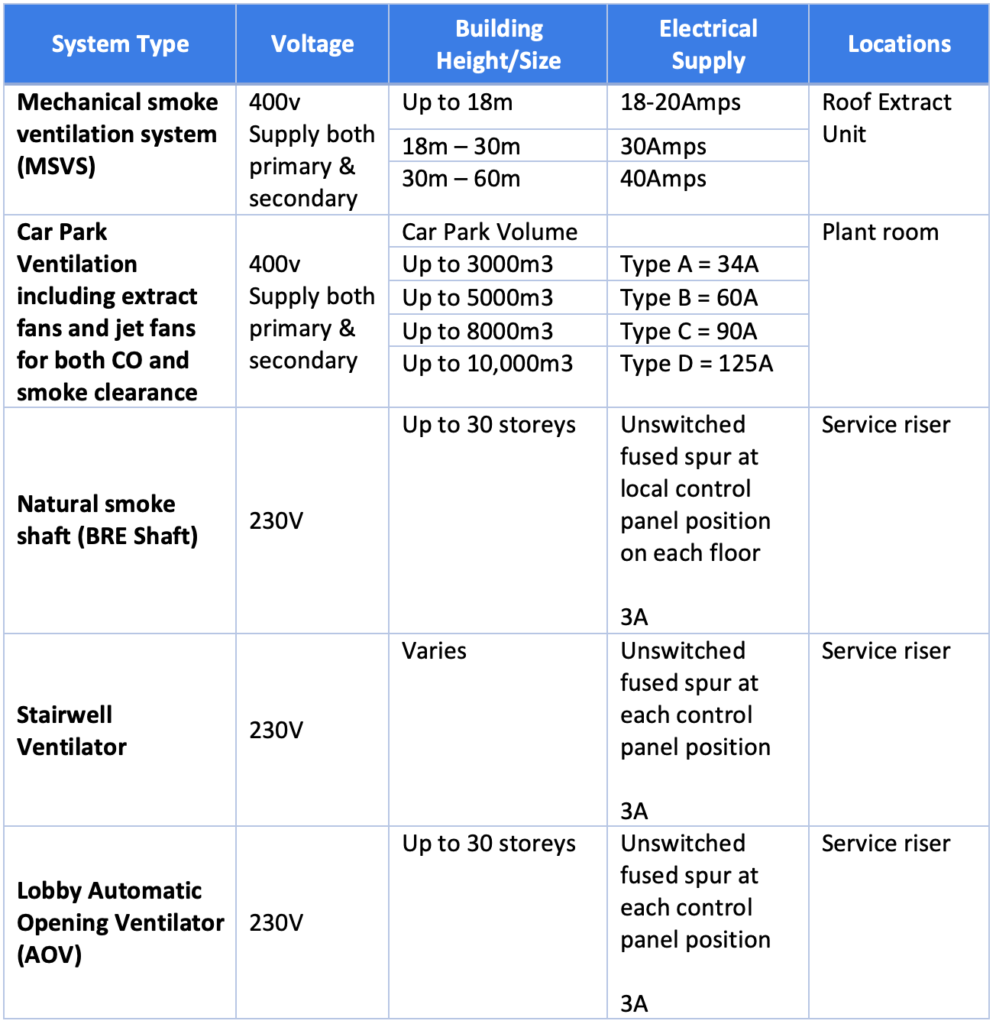

Luckily, smoke control systems, particularly those for the escape routes of tall buildings, lend themselves to a modular approach. The majority of smoke control systems share similar characterestics so the table below can be applied to a wide variety of systems.

One of the available solutions is our range of standardised modular systems, which are available off the shelf. Our systems are supported by full technical manuals available online even before purchase, which makes them ideal for early-stage allowances for plant space, power requirements, and builders’ work.

Mechanical Smoke Control Systems

For mechanical systems, the primary and secondary power cables should only come together in the fire-resisting enclosure or fire-resisting roof area housing the fan control panel by means of an automatic transfer switch (ATS) conforming to BS EN 60947-6 Low-voltage switchgear and controlgear – Part 6-1. Multiple function equipment. Transfer switching equipment. Additionally, the fan control panel should be provided with a minimum of 60 minutes of fire-resisting construction.

Natural Ventilation Systems

Traditionally, for natural smoke ventilation systems, the power supplies are provided with battery back-up and must comply with BS EN 12101-10 Smoke and heat control systems – Part 10: Power supplies.

Power Supply Size Requirement Guide

For Smoke Ventilation Systems