The UniJet car park ventilation system delivers combined pollution and smoke clearance using Jet or Impulse fans to provide an energy efficient and safe solution whilst requiring the least possible plant space. The system comprises a refabricated extract unit that exhausts smoke and pollution to the atmosphere with strategically positioned jet or impulse fans used to move stale air or smoke to the extract unit location.

Fully automatic controls monitor carbon monoxide levels and smoke or temperature conditions within the car park and operate the fans at the appropriate level, maintaining safe and comfortable conditions within the car park quietly and efficiently.

Protecting Car Parks with perfectly matched products

![]() Extract Plant Room – a complete fire rated plant room including extract fans, dampers, silencers, main control panel, automatic transfer switch, inlet grille and outlet connection.

Extract Plant Room – a complete fire rated plant room including extract fans, dampers, silencers, main control panel, automatic transfer switch, inlet grille and outlet connection.

![]() Jet or Impulse Fans – high efficiency axial flow fan with adjustable blades located to achieve the required performance.

Jet or Impulse Fans – high efficiency axial flow fan with adjustable blades located to achieve the required performance.

Control System – an intelligent PLC based modular control system using a proven fieldbus open protocol to interface with hardware.

Control System – an intelligent PLC based modular control system using a proven fieldbus open protocol to interface with hardware.

![]() Touchscreen central control panel for commissioning, testing and monitoring of system.

Touchscreen central control panel for commissioning, testing and monitoring of system.

Where can I use it?

The UniJet Car Park Ventilation System is suitable for all covered car park environments within the criteria below:

- Single level car parks with a maximum volume of 10,000m3

- A single extract point

- Replacement air drawn from the entrance ramp

- Minimum distance between extract point and replacement air source must equal 2/3 the length of longest side of the car park

Example arrangements

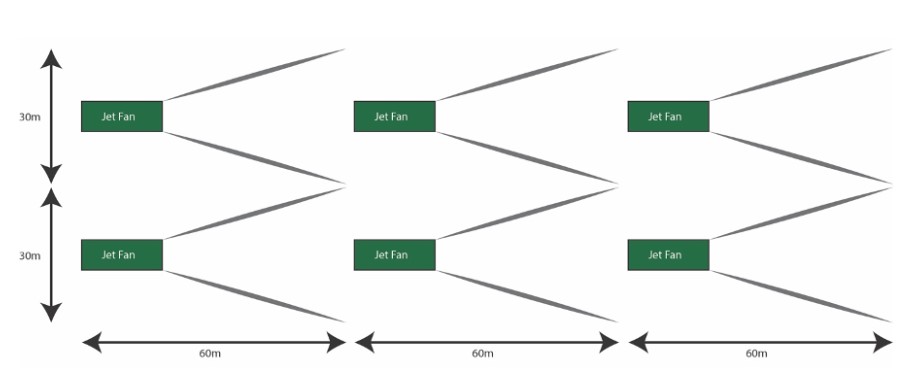

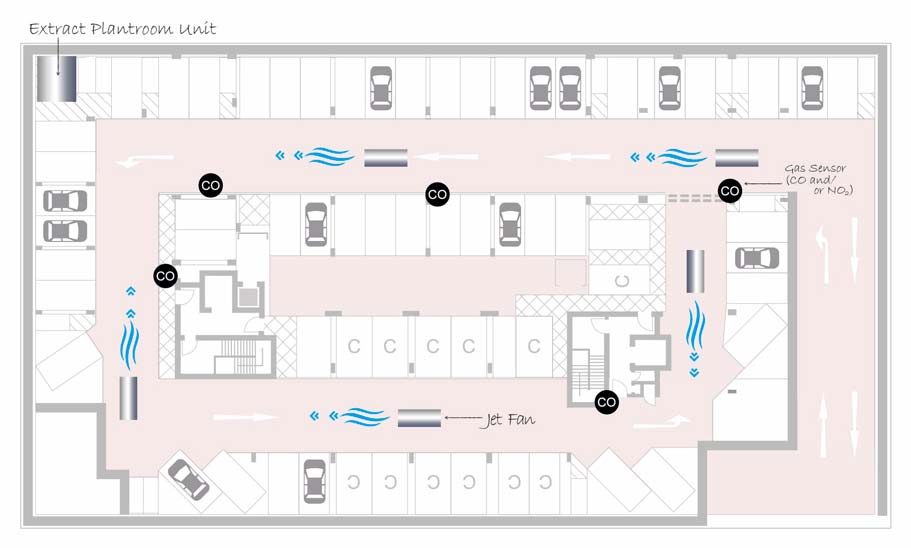

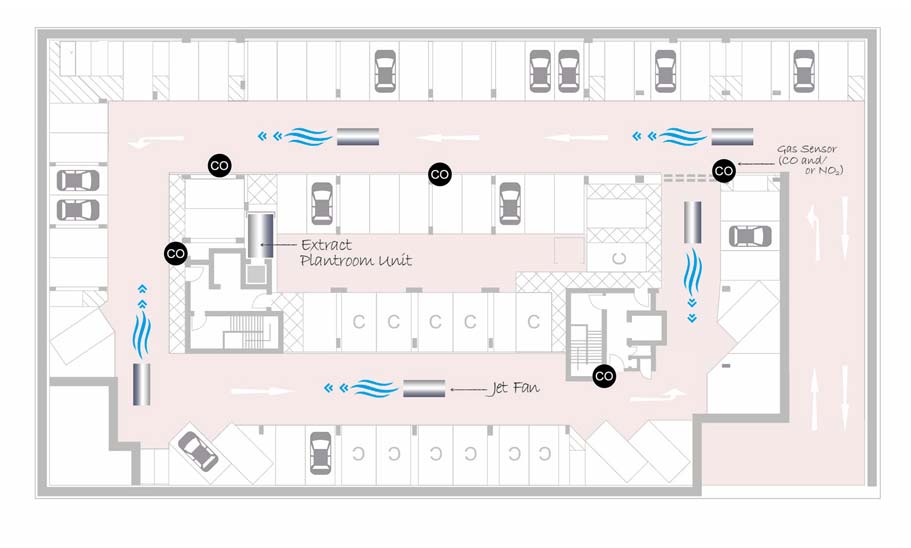

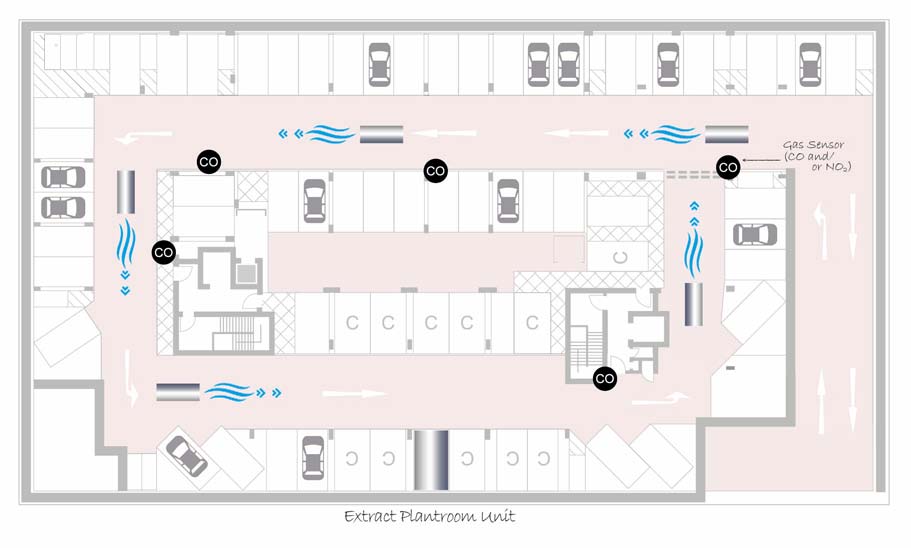

Jet fans are located strategically around the car park to distribute air evenly to the extract point. A notional number of fans is included within the system budget based on the car park volume.

Our technical team will confirm the precise positioning during the design phase.

Some typical layouts are shown below.

Fire engineered for energy efficiency

The system features a fully automatic intelligent control system that constantly monitors the carbon monoxide levels within the car park and sequentially operates fans to maintain optimal internal conditions in the most energy efficient and quiet manner.

When smoke clearance is required, all fans operate at high speed to provide a minimum extract rate of 10 air changes per hour as specified in Approved Document B.

Third-Party Certified

UniJet meets all of the relevant standards and is implemented by trained third party certified installers.

BS EN 12101 – Smoke and heat control systems Compliant

Part 3 – Specification for powered smoke and heat exhaust ventilators.

Part 7 – Smoke duct sections.

Part 10 – Power supplies.

System Selection

| System Type | Car Park Volume m³ | Plantroom model | Quantity of fans |

|---|---|---|---|

| CPV/750 | 2000 | A | 2 |

| CPV/1000 | 2750 | A | 3 |

| CPV/1250 | 3400 | B | 4 |

| CPV/1500 | 4125 | B | 4 |

| CPV/1750 | 4800 | B | 5 |

| CPV/2000 | 5500 | C | 6 |

| CPV/2250 | 6200 | C | 7 |

| CPV/2500 | 6800 | C | 7 |

| CPV/2750 | 7500 | C | 8 |

| CPV/3000 | 8200 | C | 9 |

| CPV/3250 | 8900 | D | 9 |

| CPV/3500 | 9600 | D | 10 |

| CPV/3750 | 10300 | D | 10 |

Send us your project details

Get guidance from our expert team today...