Servicing a smoke control system is essential to the safety of building occupants. Moreover, in case of a fire, it also protects and assists firefighters in accessing the premises. To ensure the safe functionality of smoke control systems, regular maintenance and checks should be performed at the premises. The Regulatory Reform (Fire Safety) Order 2005 (PRO) details the smoke control maintenance regulations surrounding life-safety systems. Unfortunately, it can often be overlooked or not fully understood.

Smoke Control Maintenance Regulations: Regulatory Reform (Fire Safety) Order 2005

According to Regulatory Reform (Fire Safety) Order 2005, the responsible person must ensure that the premises, facilities, equipment, and any devices for use by or for the protection of firefighters and relevant persons, are subject to a suitable system of maintenance and are maintained in an efficient state, in efficient working order and in good repair.

According to Regulatory Reform (Fire Safety) Order 2005, the responsible person must ensure that the premises, facilities, equipment, and any devices for use by or for the protection of firefighters and relevant persons, are subject to a suitable system of maintenance and are maintained in an efficient state, in efficient working order and in good repair.

The Regulatory Reform (Fire Safety) Order 2005 states that it is an offense for any responsible person or any other person with control of premises, to fail to comply, where that failure places one or more relevant persons at risk of death or serious injury in the case of fire. Therefore, we understand from the RRO that life-safety systems must be maintained by law. Failure to do so could result in death or injury and prosecution for failing to comply.

How often should my smoke ventilation system be serviced?

BS EN 12101 and BS 9999

BS EN 12101, Smoke and heat control systems and BS 9999, Code of practice for fire safety in the design, management and use of buildings set out the frequency of tests and what should be checked during a smoke control maintenance visit. All in all, there are three types of services – weekly, monthly, and annual. It is essential and mandatory that smoke control systems are serviced annually by a competent person. Additionally, weekly and monthly tests should be performed to ensure the system is fully operational throughout the year.

Weekly Smoke Vent System Operational Tests

Weekly tests of the system should be carried out to check the operation of the system. For mechanical systems, checks should be made to determine whether the fans are running satisfactorily and whether the ventilation system has operated. Where there is a backup generator in place, the fuel level should be checked and topped up as necessary.

Monthly Smoke Vent System Tests

Monthly tests should be carried out in addition to weekly tests. During the monthly test, the failure of the primary power supply should be simulated and a check made that the system has automatically switched over to the secondary power supply. Where the secondary supply is via a backup generator or power cell (battery or UPS), the secondary supply must be able to energise the system for a minimum of three hours. A zero airflow condition should be simulated to check that the system switches automatically to the standby fan/s and that they are running satisfactorily.

The weekly and monthly checks are typically carried out by general maintenance personnel for a building. Usually, they have received basic hands-on training from the manufacturer/installer of the system. If the systems are maintained by a competent organisation, they will at best be tested at six-month intervals during smoke control maintenance visits.

Smoke Control Maintenance Competency

Without a doubt, regular smoke control maintenance is essential. On top of performing checks, this means ensuring the correct person is doing the maintenance. Most importantly, they should have the competence to follow the relevant smoke control maintenance regulations.

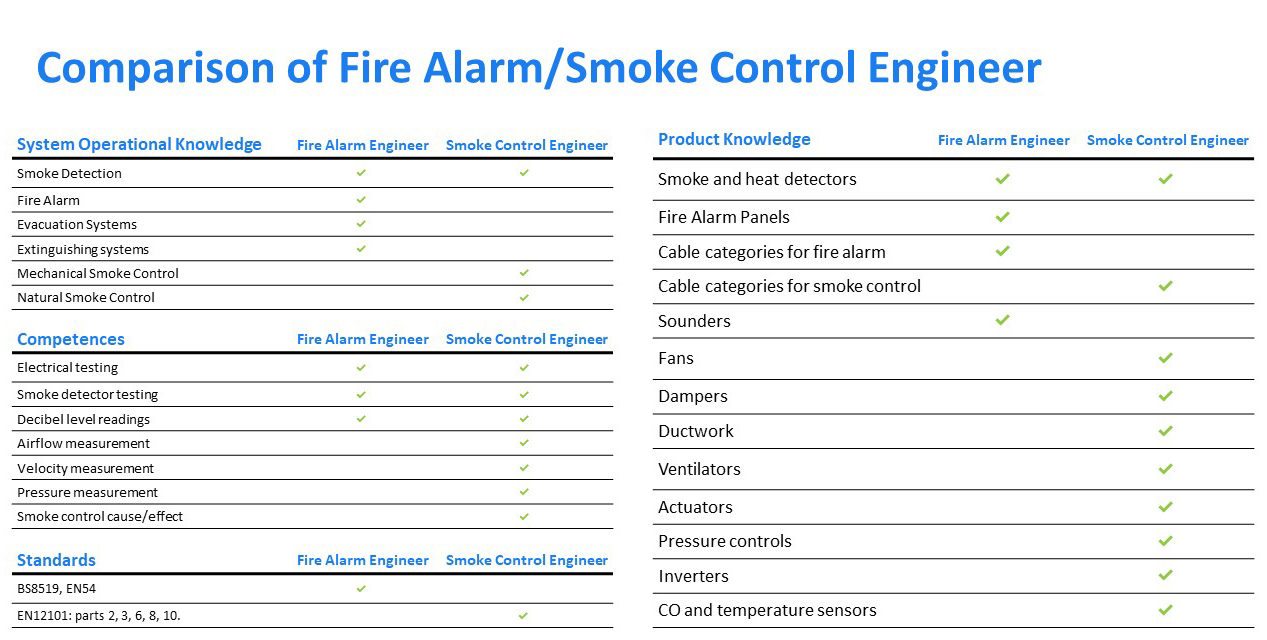

Unfortunately, it is common for smoke control maintenance to be bundled with fire alarm maintenance. However, there are vast differences in the skill sets of the people who operate and maintain such systems. We put together a comparison of skills to illustrate the difference in skillsets.

Smoke Control Engineer vs Fire Alarm Engineer

Overall, the skillset of a smoke control engineer is very different from that of a fire alarm engineer. It encompasses air flow and pressure differential measurement, fan, damper, and ventilator testing, as well as smoke and CO detection. In many cases, a fire alarm engineer may not be equipped to carry out the checks required to confirm the correct operation of most mechanical smoke control systems.

BS 7346-8:2013 – The Forgotten Code of Practice

Maintenance and compliance are two of the most discussed topics in the industry and the key to both lies in an often overlooked, but essential code of practice – BS 7346-8:2013. BS 7346-8:2013 provides a roadmap for the successful delivery of a smoke control solution from design through to handover and maintenance and it can be applied to all system types. Some of the key details the code offers are:

- A definition of the key processes to be managed

- Description of roles and responsibilities for them

- Clear guidance on performance requirements and documentation to be provided

Evidence of compliance is required throughout the lifetime of the project and there are useful templates for areas like handover and performance testing. Moreover, clause 9 covers maintenance and servicing in some detail and should be the template that all companies in this field follow.

Third-party smoke control maintenance certification

The Smoke Control Association (SCA) is the voice of the smoke control industry. Its members have to adhere to a strict code of conduct that includes being third-party certificated under the IFC SDI 19 Certification Scheme (developed by the SCA in partnership with IFC Certification).

The IFS SDI 19 Scheme can be applicable to competence in both maintenance and installation. Given that the scheme is based on the requirements of BS 7346-8:2013 (Components for smoke control systems. Code of practice for planning, design, installation, commissioning, and maintenance), it covers some of the main competencies involved in smoke ventilation system maintenance.