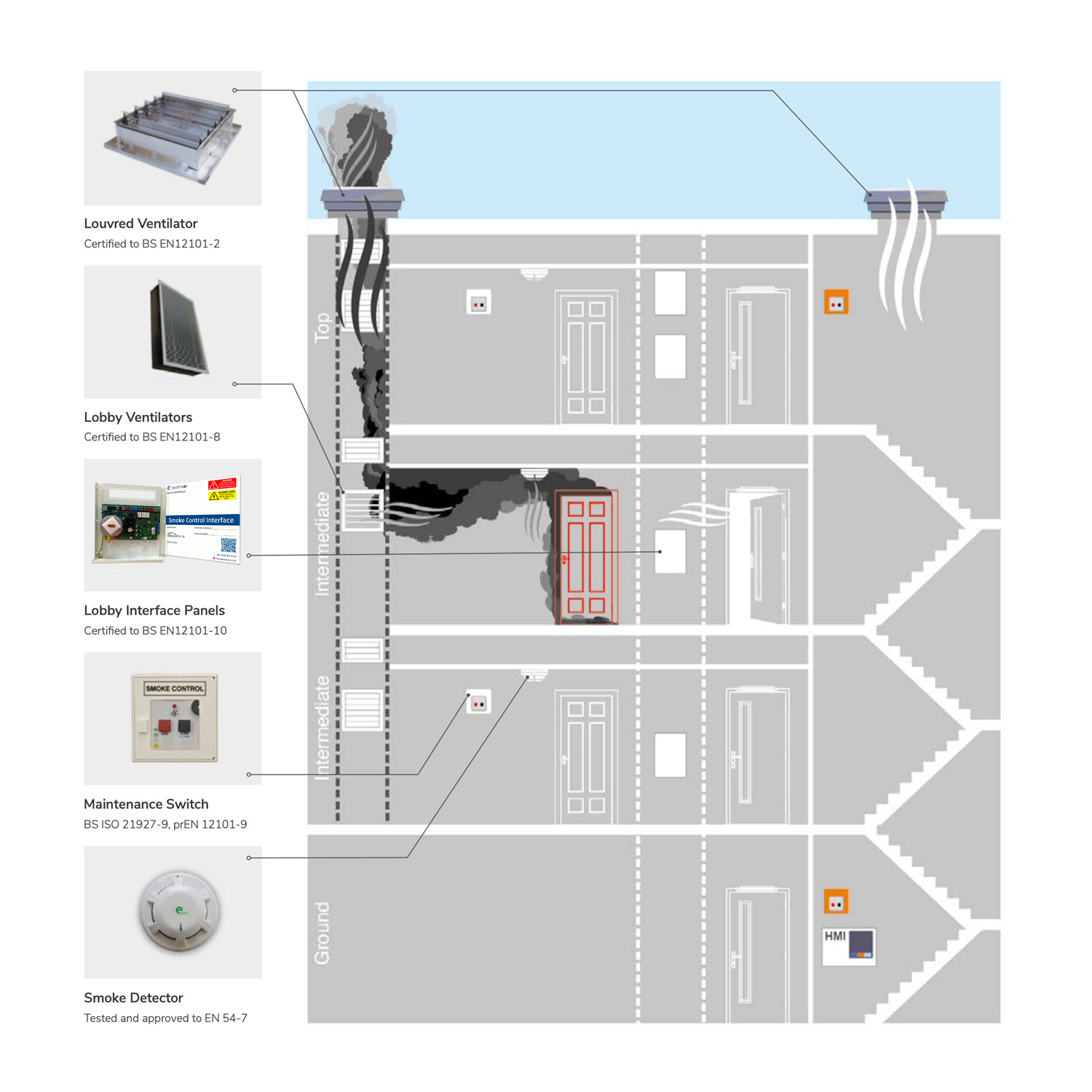

Smoke Extract Fan Components

Fans

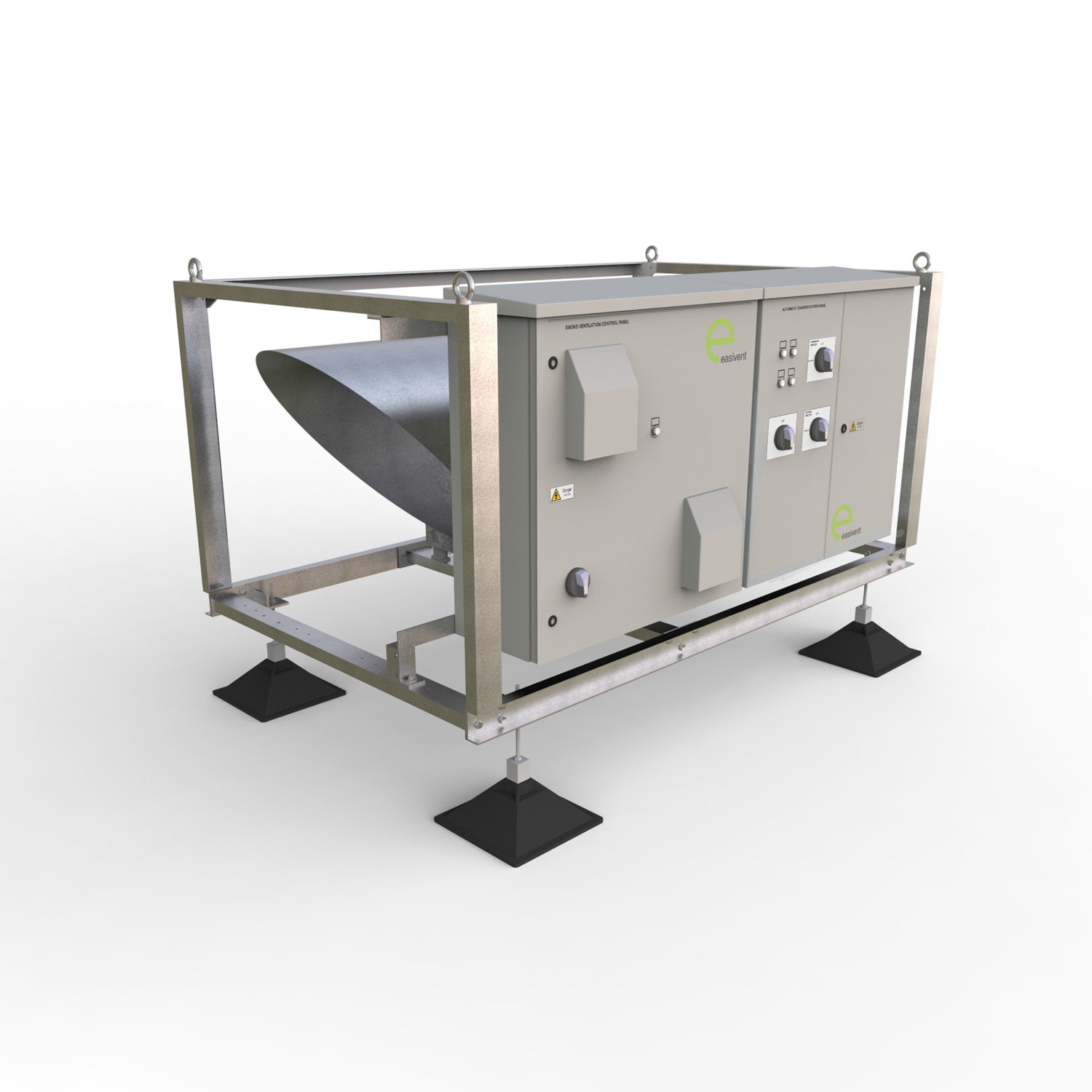

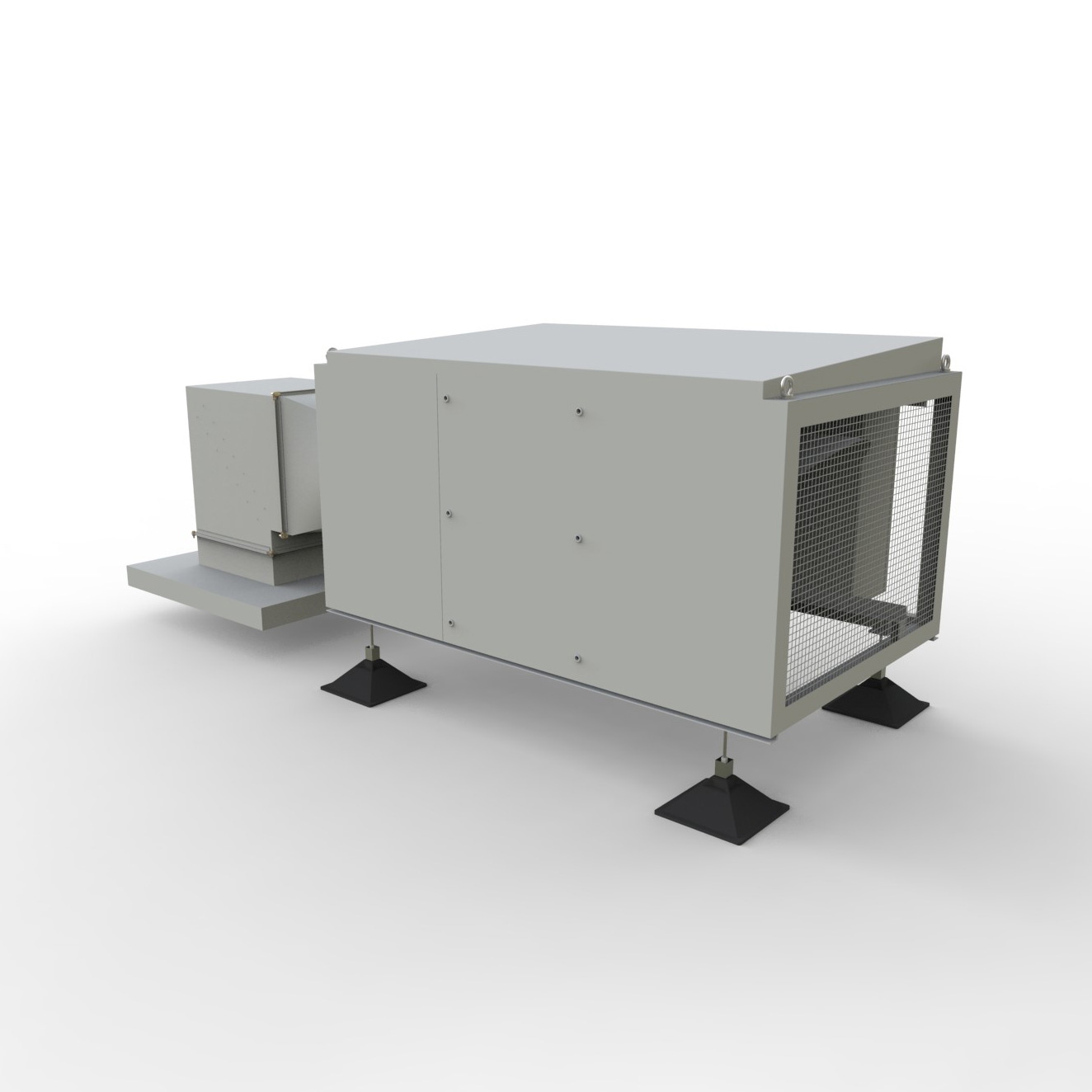

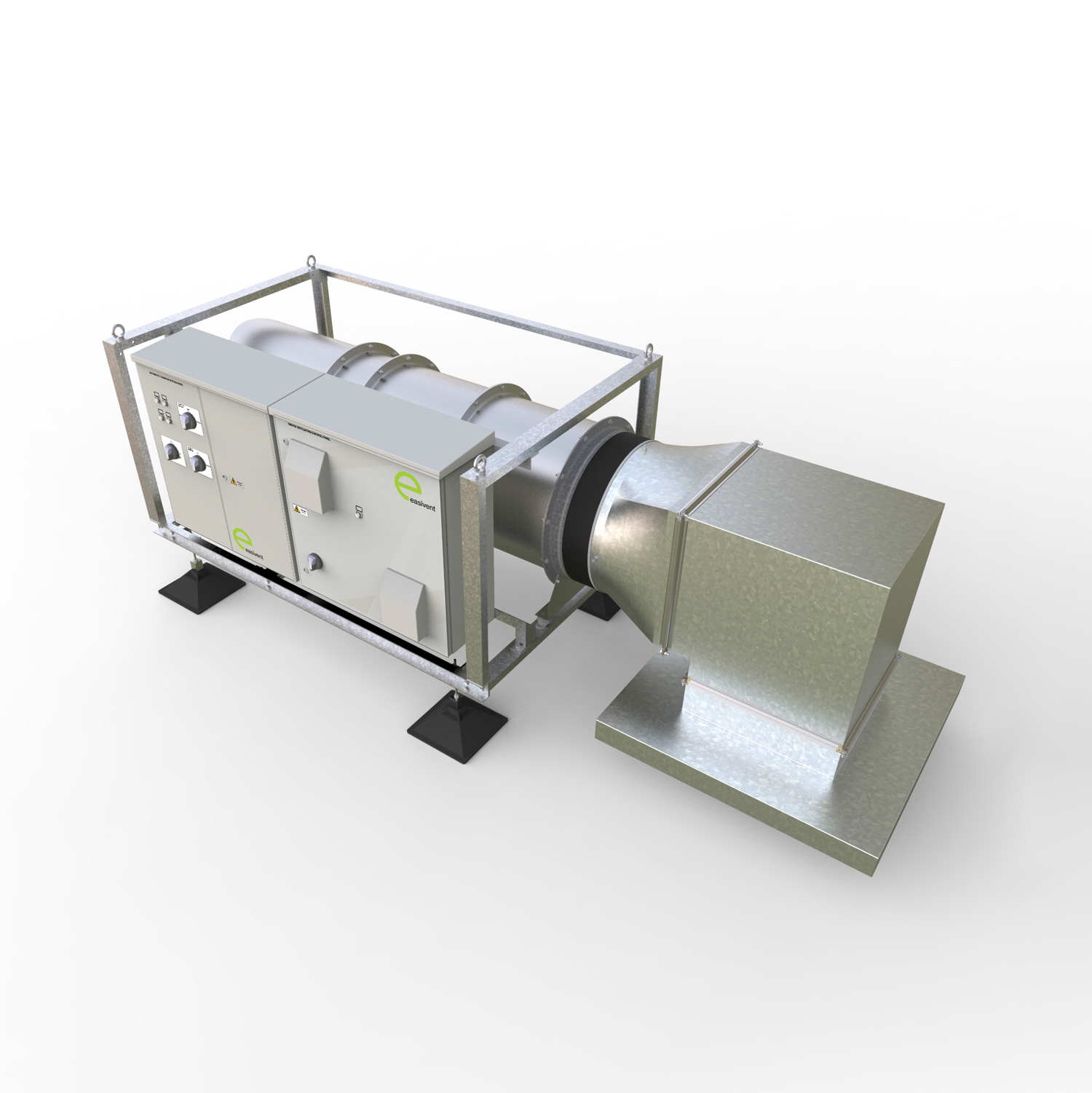

The smoke extract fans are axial high-temperature fans, manufactured from hot-dipped galvanized steel sheets. All fans are tested to the latest internationally recognised standard ISO5801 Part 1, installation category D for aerodynamic performance, and BS848 Part 2 (1985) for acoustic performance. The fans and motors are rated at 300°C for 2 hours and are fully tested and certified to the requirements of EN12101-3. The fans are mounted in series onto a pre-assembled module using anti-vibration mounts. The fan assembly will contain a weatherproof discharge, a flexible connector, a gravity shut-off damper, and a fire-rated galvanised steel plenum section connected to the builder’s work roof up-stand above the extract shaft. The fan assembly will be mounted onto skids fitted with adjustable feet for mounting on a suitably prepared roof area.

Control System

The main system control panel is also located on the skid and pre-wired to the fans and dampers. An integral motor control centre provides the control and monitoring of the extract fans, dampers, doors, and stairwell AOVs through the communications network. The operation of the fans is to be monitored by current sensing so that in the event of fan failure the standby fan will be automatically started. All extract fans are inverter-controlled by the extract fan control panel. This is done in order to reduce starting currents and allow for adjustment of volume flow rates so that the required extract rates are achieved at the point of extract within the corridors. In fire conditions inverters operate in a run-to-destruction mode.

ATS Switch

Auto changeover of mains and standby power supplies is provided by an optional automatic transfer switch (ATS) module mounted on the common plant skid where required. The ATS is fully compliant with BS EN 8519:2010 with a bypass feature to maintain a fully operational system during maintenance work.

Under the Construction Products Regulations (CPR) it is a legal requirement to use only certified products for smoke ventilation. It is the responsibility of the installer to ensure installations meet the relevant standards. For more information see SCS Group’s Technical Bulletin.